Posted by Chuck Iker, Iker Bonsai Pots on 4th Nov 2025

Blending Tradition and Tech in Bonsai Pottery

Exploring a Little Technology in My Handmade Process

Lately I’ve been exploring how a little technology can fit into my old-school, hands-on pottery process. I’ve always embraced the natural flow of hand-formed and thrown pieces. I’ve never pursued high-volume matched sets or developed a line of pottery. I’ve never used molds, jiggers, or complex formed ribs in my making process.

My work is one of a kind, and I tend to let the clay drive the form. I deeply respect the discipline and skill required to replicate the same form over and over, but my own rhythm is more intuitive and yields variety in output that better matches the styles of pots I want to produce. Each has its own design consideration.

When My Process Met a Laser Cutter

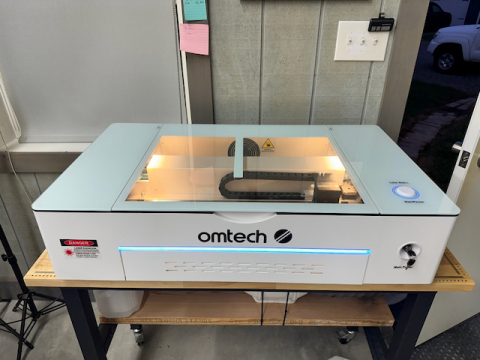

Last year, though, my longtime process crossed paths with a little technology: laser cutters. They’d been on my radar for a while, probably a remnant of my technical background and interests.

Could this technology fit into my handmade process without dulling its soul? Eventually, curiosity won. I finally settled on a CO₂ laser that felt right for the studio. I’m not here to review the machines—just to share what happened when I let it into my process.

A Surprisingly Versatile Tool

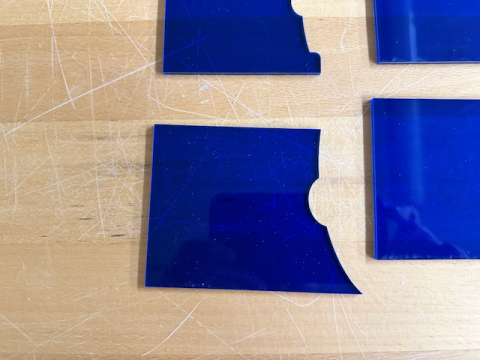

This tool has proven to be surprisingly versatile. It cuts wood, plastic, silicone, and hard rubber, which means I can design and make my own pottery tools—ribs, trimming tools, stamps, and more—all customized for the application I need.

One example: a longtime customer of mine had an idea for a custom pot with a wide, rounded band around the middle outside. That’s not an easy form to throw cleanly. So I designed and cut a rib using the laser. Normally, I stay away from anything that feels like a template, but this one? It made the form possible without feeling mechanical. It was still very much my hand guiding the process.

Custom Clay Stamps

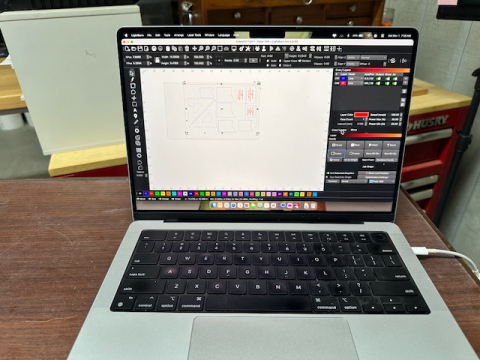

My favorite discovery so far has been the creation of custom clay stamps. The laser’s built-in scanner can take a hand-drawn signature or picture and turn it into a perfect, cut-ready design.

You can literally sign your name on a scrap piece of paper, scan it, resize it, and cut the negative so it stamps cleanly in the clay. One of the first projects was a stamp of my bonsai logo I made for mugs I give to friends and family around the holidays. I also offer these on my website in a limited and numbered release.

Beyond Stamps

Sure, you could buy dozens of custom stamps for what the cutter costs. But the freedom to make what you want—any time, any size in about 15 minutes—is something else entirely.

And it goes beyond stamps. Say I’m throwing a pot and can’t quite get the rim profile where I want it. I can sketch the line, scan it, and cut a custom rib while the clay is still on the wheel. I also understand that making adhesive-backed thin masks is possible. I haven’t tried that yet, but no doubt I will.

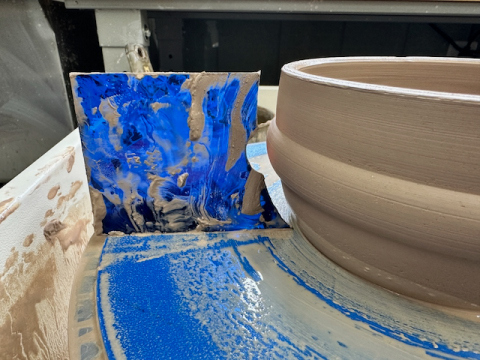

Keeping the Handmade Soul

My concern was that having this capability in the studio might drive a more mechanical feel or make it tempting to shortcut the hand-formed process. The fact is, it does offer that possibility—I just don’t allow myself to go that route.

Looking ahead, I see real potential in creating custom or personalized stamps for gifting or commemorative pieces. Years ago, I was asked to make a set of wine goblets for a small rural church that wanted a few religious images on them. It was mostly a favor, and I ended up overcommitting on the design work. To pull it off, I hand-carved each image from rubber stamp material so I could press them into the clay. It took forever, and I was never completely satisfied with how they turned out—though, fortunately, my friend was thrilled. Having the equipment I do now would’ve made that project a whole lot easier—and a lot more fun.

Just Another Tool in the Kit

This tool is just another in the kit. I still look over at it in the studio and wonder if it belongs there. But when it pulls me out of a tough form or extends my capability a bit, I think it does.